You might also be interested in this

Simulations are Key to Designing a Tube System

Reading Time: 2 min.

11/9/2023

Vaibhav Barot

Tube simulations in the pneumatic systems space have been an integral part of engineering workflows for the last couple of decades. Typically engaged during the early stages of project planning, these simulations offer valuable insights into design efficacy, optimization opportunities, and reliability factors.

In their absence, the risk quotient for design errors and operational inefficiencies would be substantially higher.

When it comes to performing a simulation for a pneumatic tube system, engineers frequently rely on advanced software tools that provide a virtual testing environment. Data driving these simulations is sourced from a mix of historical records , established operational benchmarks, and in some cases, future-focused analytics.

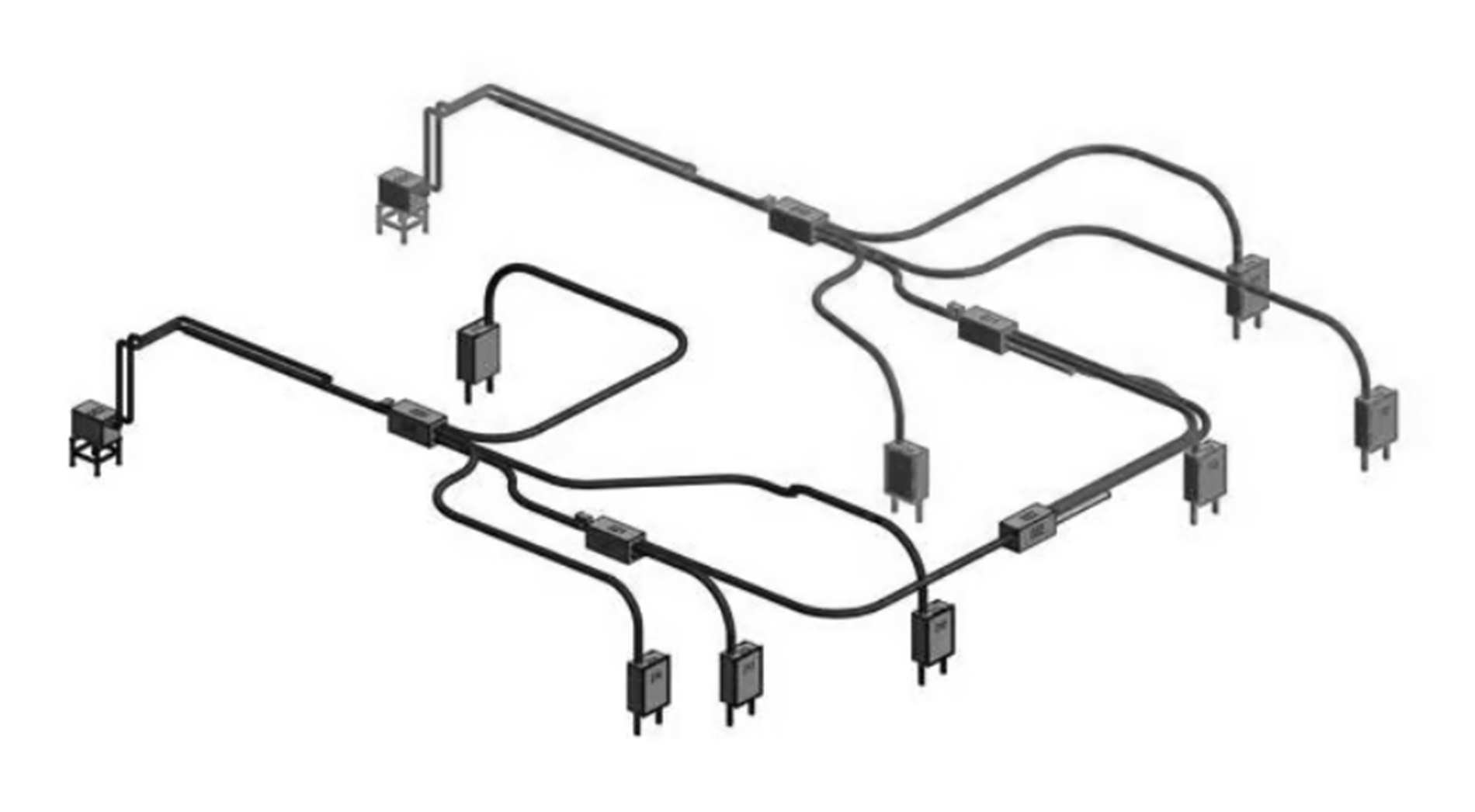

The time commitment for a simulation varies, often spanning from several hours to multiple days, based on the project's scope and complexity. What sets our team apart is our nuanced understanding of pneumatic tube systems, our large data set, our ability to generate accurate 3d models of complete systems, and years of hands-on experience in the field.

The utility of these simulations often manifests in substantial alterations to a project's initial design, focusing on enhancements in system efficiency and dependability. For example, the simulations can identify potential system issues, such as bottlenecks, that may require design modifications.

A recent case in point: simulation insights led to a rethinking of tube routing, which subsequently cut material expenses by a fifth and significantly accelerated the project timeline.

Today, using pneumatic tube system simulations is standard industry practice, serving essentially as a proactive risk mitigation strategy. These simulations offer a virtual sandbox to model different operational scenarios, preemptively identifying issues and thus leading to cost and time savings down the road.

With over 100 years of data on hand, TransLogic experts are able to design systems that meet the customer's both now and in the future.

Contact our knowledgeable specialists to discover how our range of automation solutions can boost efficiency, reduce costs and enhance care at your healthcare facility.

Contact us