Why Design Assist is a Win-Win:

Once the general contractor begins construction, major modifications to the design can result in serious logistical hurdles that can kick off a chain-reaction of unintended delays, permitting issues, material waste, and costly down time.

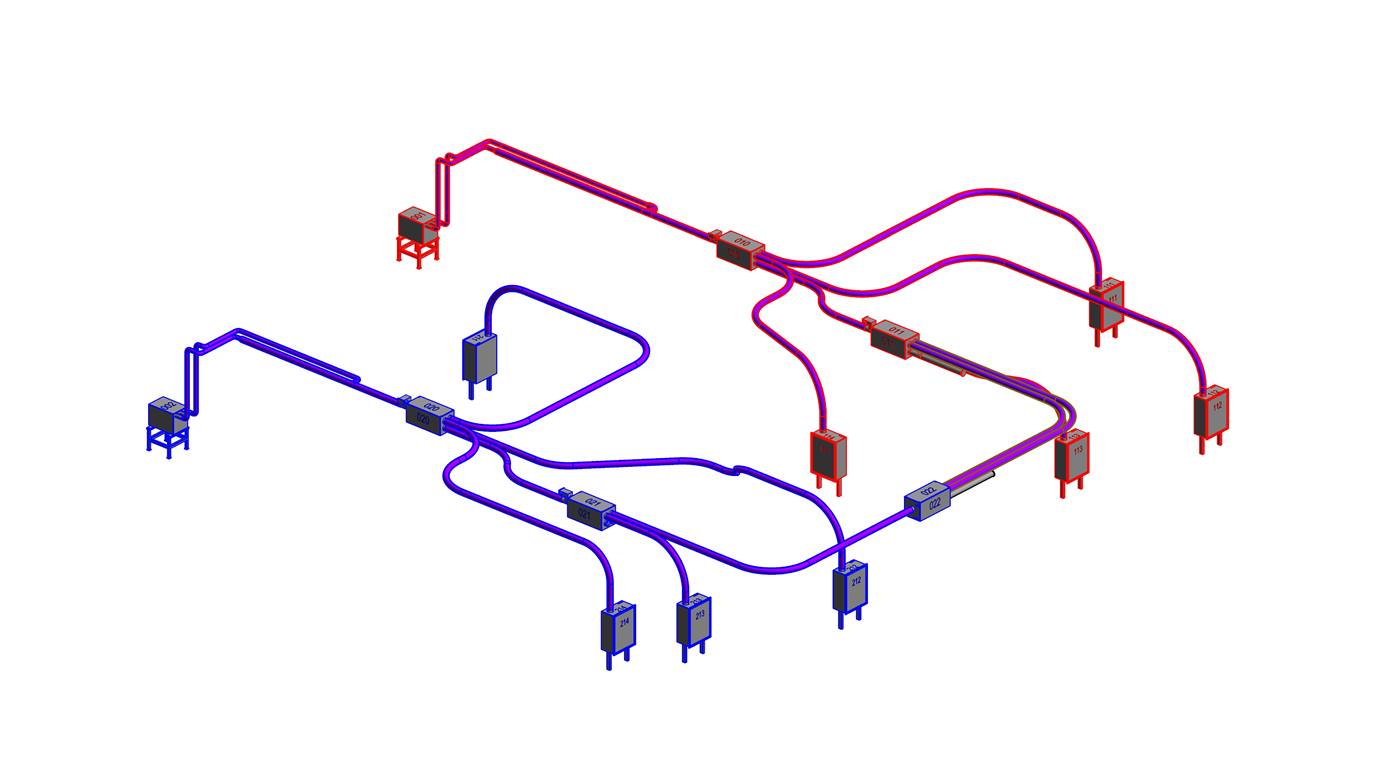

Using the TransLogic Design Assist service early in the design process gives you the opportunity to draw on our 100+ years of tube system experience. Our experts offer their guidance and run custom-tailored computer-based simulations to evaluate the following aspects of a custom pneumatic tube system:

- Blower systems: the number of blowers, types of blowers, size of blowers, location of blowers, performance requirements.

- Stations: the number of stations, station locations, types of stations.

- Tube design: the number of offsets in a given system, strategic placement of transfer control units or transfer units.

- Electricity/power: the required power infrastructure to maintain operations.

- Physical dimensions/space: how well the system fits alongside other infrastructure.

- Service access: accessibility of the critical components. Both regular maintenance and emergent repair should be able to be completed swiftly.

- System performance: system designs that meet the client’s specific needs.

- Special considerations: clients regularly require a unique build out for things such as transporting radioactive specimens, connecting multiple buildings, etc.

The result is a design that streamlines the implementation process while maximizing performance, efficiency, and reliability — with significant financial savings, now and in the long run.